Pre-Directive Machinery: what should companies do?

Many companies, especially in the manufacturing sectors, still use pre-directive machines, built before the Machinery Directive (89/392/EEC) came into force. But what does it mean to have this equipment in operation today? And, above all, what should be done to ensure safety and avoid penalties?

Pre-directive machines, i.e. machines built before 1996 (the year in which Directive 89/392/EEC was implemented in Italy) are not subject to the CE marking requirement. However, this does not mean that they can be used without any adaptation.

In any case, they must comply with the minimum safety requirements established by Title III of Legislative Decree 81/2008 and in particular with the safety requirements established by Annex V of Legislative Decree 81/2008. Essentially, for machines built before 1996, it is necessary to assess their conformity with current safety requirements, which may include:

Documentation: draw up a declaration of conformity or a certified report attesting to the safety of the machine.

- documentation: drafting a declaration of conformity attesting to the safety of the machine,

- safety check: verification that the machine is suitable for use and does not present significant risks for operators,

- technical adaptation: if necessary, make changes to improve safety, such as installing additional protections or safety devices,

- other measures such as training activities for relevant personnel and operating procedures.

Furthermore, all equipment and machinery must be regularly maintained and used in accordance with the instructions and all relevant documentation.

Be used in accordance with the instructions

Risks for companies

In addition to the real risk to workers, the use of non-compliant pre-directive machinery can lead to sanctions. The recent joint note of the National Labor Inspectorate (INL) and the Conference of Regions (March 2025) clarifies that sanctions also apply to pre-directive machinery if equivalent safety measures are not adopted.

Examples of punishable irregularities are the lack of fixed or movable protections, non-functioning or absent arrest systems, the absence of updated manuals or operating instructions.

Common mistakes to avoid

Often in good faith, mistakes can be made that expose one to risks and sanctions, such as considering a machine “compliant” just because it has always been used. The length of use does not guarantee compliance: conditions change, standards evolve, risks can increase.

A generic risk assessment that does not analyze the specific dangers of individual machines is another mistake. Sometimes guards interfere with productivity and for this reason they are removed. The removal and in general the absence of guards is a major cause of accidents and fines.

Operators who use a machine must know its limitations, proper use, and safety measures. Inadequate operator training poses a risk to both the individual operator and the company.

How to intervene?

The first step to start with is often overlooked but fundamental: make a complete census of the machines present in the company, noting the essential information such as identification plates, model and condition. From this census you will have a detailed picture to determine:

- what are the pre-directive machines,

- which machines are CE compliant,

- which machines require urgent intervention.

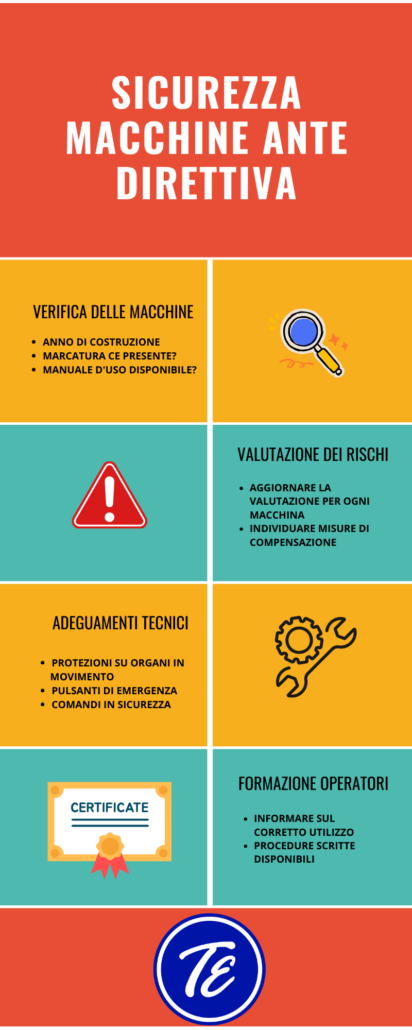

The infographic above represents an operational checklist useful for RSPP and Employers:

🔍 Verifica dello stato delle macchine

- Anno di costruzione.

- Presenza o meno della marcatura CE.

- Presenza del manuale d’uso originario.

📄 Valutazione dei rischi specifica

- Redazione o aggiornamento della valutazione dei rischi per ogni macchina.

- Identificazione delle misure di compensazione (es. barriere fisiche, segnali di avviso).

🛠️ Adeguamenti tecnici

- Installazione di protezioni su organi in movimento.

- Inserimento pulsanti di emergenza.

- Adeguamento dei comandi secondo criteri di sicurezza.

📚 Formazione degli operatori

- Informare e formare il personale sull’utilizzo corretto e sui limiti della macchina.

- Redazione di procedure operative scritte.

Circolare INL n. 2668 del 18 marzo 2025

Il 18 marzo 2025 l’Ispettorato Nazionale del Lavoro (INL) insieme alla Conferenza delle Regioni e delle Province Autonome ha pubblicato la Circolare o Nota n. 2668 per fornire alcuni chiarimenti operativi e interpretativi sull’applicazione del Testo Unico sulla Sicurezza sul Lavoro, il D.Lgs. 81/2008. La nota si concentra in particolare su due temi principali: l’applicazione delle sanzioni per violazioni riconducibili a categorie omogenee e la conformità delle macchine prodotte prima della Direttiva Macchine (89/392/CEE).

Sanzioni per categorie omogenee

La violazione di più precetti appartenenti alla stessa categoria omogenea (ad esempio, requisiti di sicurezza relativi ai luoghi di lavoro di cui all’Allegato IV del D.Lgs. 81/2008) costituisce una violazione unica, punita con una sola sanzione. Al contrario, la violazione di precetti appartenenti a categorie diverse comporta l’applicazione di più sanzioni.

Conformità delle macchine ante Direttiva Macchine

Per le macchine prodotte e utilizzate prima del 21 settembre 1996, la nota specifica che il datore di lavoro deve garantire la conformità ai requisiti generali di sicurezza di cui all’Allegato V del D.Lgs. 81/2008. Non è previsto l’obbligo di un’attestazione di conformità firmata da un tecnico abilitato, ma durante le ispezioni si verifica la corretta valutazione dei rischi e la conformità ai requisiti di sicurezza.